Noise Control Product Type

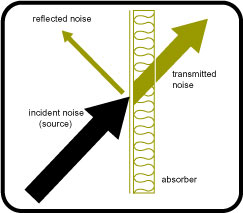

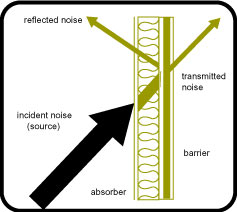

ABSORBERS

Use: To reduce noise reflection. To dissipate noise energy.

Use: To reduce noise reflection. To dissipate noise energy.

Physical Properties: Porous, fibrous and sometimes covered with protective membranes. Noise enters the absorber and is partly dissipated (absorbed) within the material. Some is transmitted. Some is reflected. Absorber performance is expressed as a decimal value. A perfect absorber is rated at 1.00. The higher the decimal value the more effective the absorber will be.

Effectiveness is expressed as NRC (Noise Reduction Coefficient).

NRC: Percentage of acoustical energy absorbed calculated as an average of laboratory test data at several frequencies.

| Noise Reduction Coefficients of Materials | NRC |

| Brick, unglazed | .05 |

| Concrete block | .05 |

| 1/8" pile Carpet | .15 |

| 5/16" pile Carpet and foam | .35 |

| Concrete floor | .00 |

| Plaster, smooth finish | .05 |

| Plywood paneling, 1/4" thick | .10 |

| Water surface (as in swimming pool) | .00 |

| 1" thick fiberglass curtain | .70 |

| 3" thick "SONEX" wedge foam | .86 |

| 4" thick smooth surface foam | .89 |

| 4" thick metal panel | .95 |

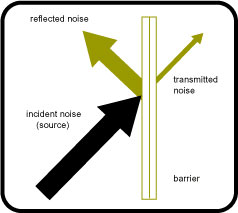

BARRIERS

Use: To block transmission of noise.

Use: To block transmission of noise.

Physical Properties: Non-porous, high density and usually non-fibrous. Barriers are generally flexible or damped. The noise is blocked, reflected and re-routed in another direction. Barrier materials are tested and rated for their Sound Transmission Loss capability. The number is stated in dB and the higher number signifies the better barrier.

Effectiveness is expressed as STC (Sound Transmission Class).

STC: Single number rating derived from decibel loss data at several frequencies.

| Sound Transmission Class of Materials | STC |

| 1 lb. density barrier material | 26 |

| 1 lb. density transparent curtain | 26 |

| 5/8" Gypsum wallboard | 30 |

| 3/16" Steel wall | 31 |

| 2" fiberglass curtain with 1 lb. barrier | 29 |

| 2" thick metal panel (solid and perforated) | 35 |

| 4" thick metal panel (solid and perforated) | 41 |

| 12" thick concrete | 53 |

| 3/8" plasterboard | 26 |

| 22 gauge steel | 25 |

| Solid core wood door, closed | 27 |

| Concrete block wall, unpainted | 44 |

COMPOSITESUse: To block the transmission of noise and reduce reflections from the barrier. Physical Properties: Consists usually of a layer of porous material and a layer of dense material. The composite material will have a performance capability as an absorber and as a barrier. Septum barriers are sandwiched between two absorber layers. Effectiveness is a combination of STC and NRC ratings. |

|

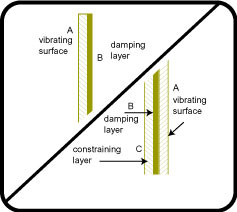

DAMPINGUse: To reduce noise radiated from vibrating surfaces. Physical Properties: Viscoelastic. Damping coatings take many forms. There are mastics for spraying, troweling, etc. and there are tapes and sheets with pressure sensitive adhesive. Damping treatments are sometimes combined with absorbers. Effectiveness is expressed as a "loss factor" which is the damping/stiffness ratio of a material. |

|

DECOUPLED COMPOSITESUse: To enhance the performance of the composite material when applied to the inside of an existing barrier. Decoupling creates an air space between the existing barrier and the septum composite barrier boosting transmission loss beyond what could be expected with direct attachment. |

|

DIFFUSIONUse: To reflect sound waves off convexly curved or uneven surfaces for the purpose of evenly distributing and blending the sound over a broad area. In critical listening environments diffusion can eliminate sharp echoes without eliminating the sound by absorbing it. |

|

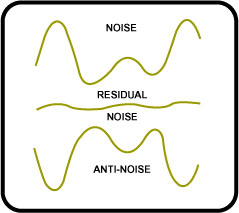

ELECTRONICUse: To cancel unwanted noise energy through destructive interference by electronically generating a 180° out of phase anti-noise which is equal and opposite in phase and amplitude. Physical Properties: Equipment includes an input microphone, controller/amplifier, speakers and an error microphone. Works best with noise propagated in a confined/closed loop space such as a pipe or duct. Works best where the noise source is repetitive and not random. Works best in low frequencies up to about 500 Hz. Effectiveness is expressed as Dynamic Insertion Loss (DIL) for active/electronic mufflers and silencers. DIL: The noise reduction of sound power level attained by inserting a silencer or muffler in a pipe or duct transmission system under air flow conditions. Technological Advances: Electronic or active noise and vibration technologies are emerging from research and development to production applications. Recent advances include cancellation headsets, mufflers for automotive and industrial and a variety of consumer appliances. |

|

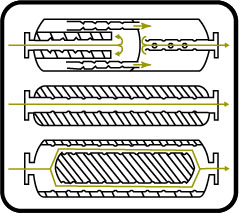

FLOW CONTROLUse: To reduce flow/fluid-borne noise transmission traveling through pipes and ducts connected to air/fluid control devices, equipment and systems. Mufflers or silencers use absorptive and reactive designs to allow air passage while attenuating the noise. Fluid-borne flow systems may be air, gases or steam. Physical Properties: Internal geometry of the flow control device dictates the overall noise reduction that can be achieved and the resultant pressure loss of the system. Absorptive designs can vary the insulation thickness and density in the wall cavity as well as the distance between internal baffles (passage width). Reactive designs can vary the flow control device internal chamber length and volume as well as the number of interconnected chambers and the size and length of choke tubes connecting the chambers. Effectiveness is expressed as Dynamic Insertion Loss (DIL) for mufflers and silencers. DIL: The noise reduction of sound power level attained by inserting a silencer or muffler in a pipe or duct transmission system under air flow conditions. |

|